Cavitymold, Inc. provides a wide range of engineering expertise and highly qualified professionals.

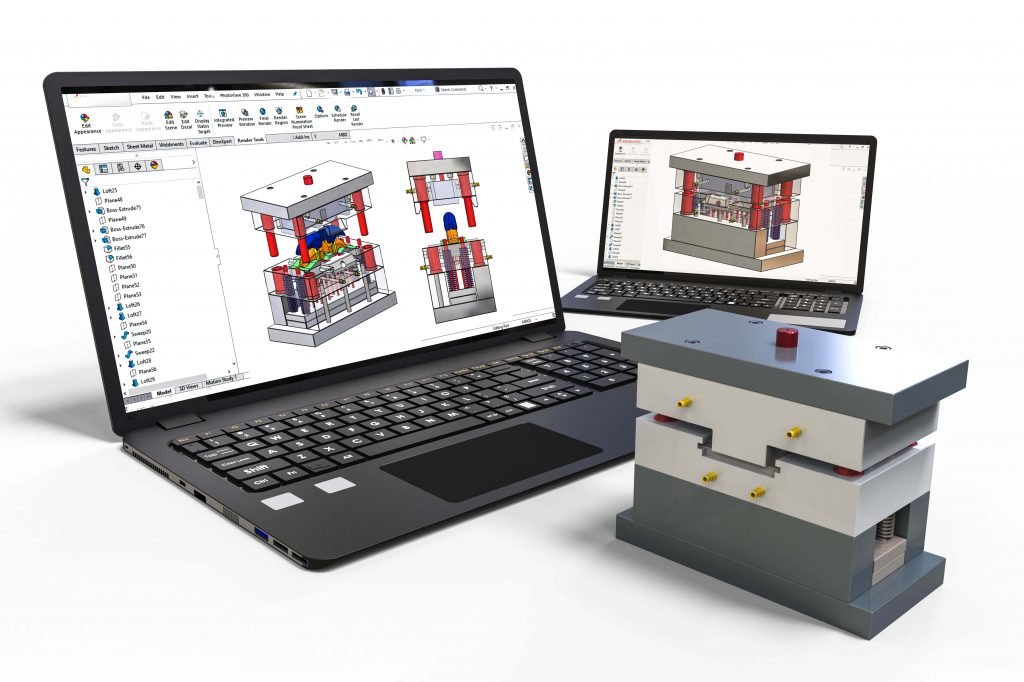

Our engineers provide a perfect combination of education, experience, and creativity. We focus on the engineering design of plastic products/components, molding tools, and home appliances. We use both 3D and 2D models in almost all modern CAD / CAM / CAE engineering software packages.

Engineering Services

• Process Validation

• Prototype Machining

• Mold Flow Analysis

• 3D Print Product

• Program Management

Drawings

The production of molded parts starts with drawings. It can be a hand-drawn sketch, a 2D PDF file, or – best of all – a 3D solid model.

Design Analysis

Once the drawing is completed, it will pass through a Moldflow analysis to ensure that the product can be injection molded with the best manufacturability. This step allows any defects in the product design to be identified and resolved before prototyping.

Prototyping and testing

Once the design is approved and analyzed, a molded prototype is produced for testing. Making a prototype is the best way to ensure that the molded part or part works as expected.

3D printing

we can provide 3D printing before mold design, it is provided for parts evaluation to test their suitability for shape or function.

To learn more about designing and testing injection molded products, click here.

Engineering Software

• Unigraphics(UG)

• AutoCAD

• Mechanical Desktop

• Master CAM

• Mold Flow MPI

File Formats

AutoCAD (DWG, DWZ)

DXF Drawing Interchange Format, or Drawing Exchange Format

IGES Initial Graphics Exchange Specification, ANSI file format.

JPG or JEPG Joint Photographic Experts Group

PDF Portable Document Format

Pro-E or Pro/Engineer (DRW, PRT, XPR)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

STEP Standard for the Exchange of Product Model Data

TIFF Tagged Image File Format

Parasolid (X_T)

Design And Project Engineering

Our engineers are experienced in working with large OEMs to develop the entire product line and small entrepreneurs trying to bring their products to market. Whether you start with a drawing or a sketch on a napkin, cavity mold can help you turn a development project into a production-ready strategy.

Analysis and Verification

Our team can work with you to review or help develop various product specifications. We can provide material consultation, mold process analysis, parts verification, cost requirements, dimensional inspection, and so on.

Product and Component Consultations

Do you have any questions about your current design, product features, or how it is made? We meet regularly with teams facing similar problems to help them understand how to use automation, assembly, and other manufacturing services to implement their products.

Program Management

Usually, it’s not cost-effective to have your own project manager in the workforce. We provide comprehensive project management, outsourcing your engineering requirements to a team that can bring your products to market while meeting specific legal and regulatory requirements.