Plastic Mold Texture: What Is Plastic Mold Texture And How Is It Textured?

Plastic parts have a significant array of appearance and texture. Plastic mold texture use for various purposes. Plastic mold surface textures are now more in

Plastic parts have a significant array of appearance and texture. Plastic mold texture use for various purposes. Plastic mold surface textures are now more in

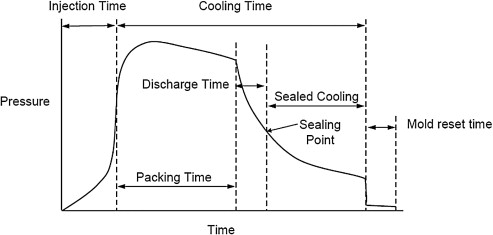

Injection molding has the potential to achieve efficient and fast plastic part manufacturing. Identical parts get made in repeated cycles without defects. Thus leading to

Injection molding is the industry’s choice for the manufacturing of plastic products. The process makes it easy to manufacture thousands to millions of identical products.

Injection-molded parts are often parts to sell as a brand new product. Customers expect manufactured goods to look perfect. The injection molding process by design

Around 32kg out of every 100kg of plastics processed globally uses injection molding. This makes injection molding an important manufacturing process. The success of injection

When searching for mold manufacturers, it is important to understand the market dynamics. You can find different categories of mold manufacturers. Some got funded by

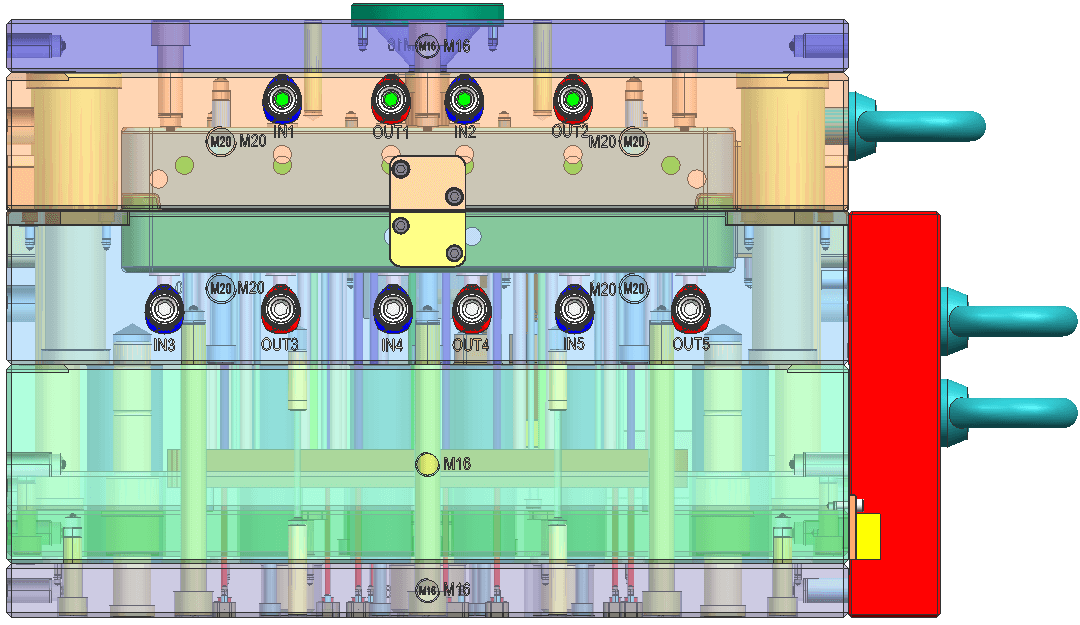

When the injection molding process runs well, it can all seem so straight forward. In reality, to ensure that every product comes out of the

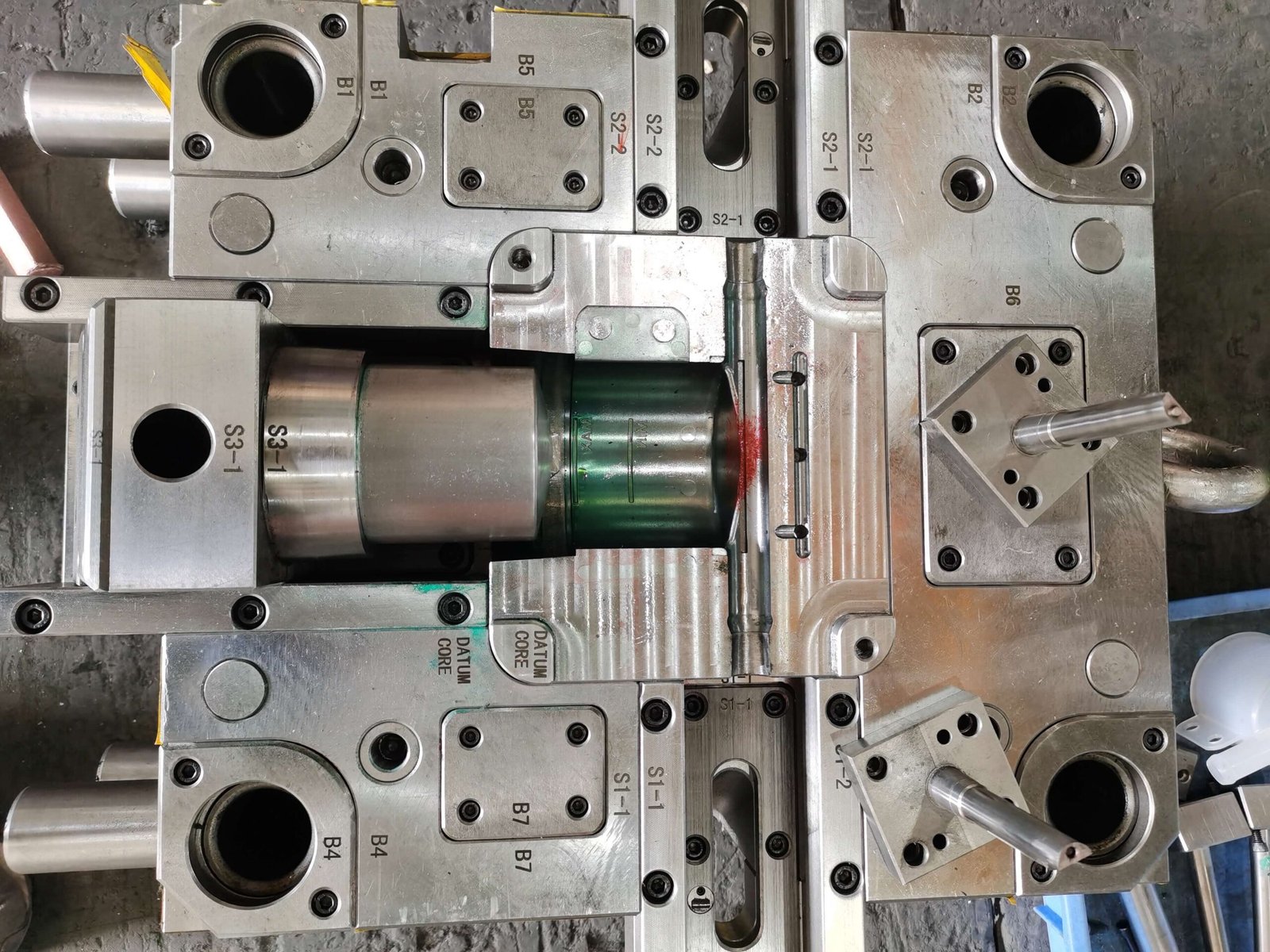

The mold is a major investment for plastic product manufacturers. It can mean a large fraction of the total cost of an injection molding machine.

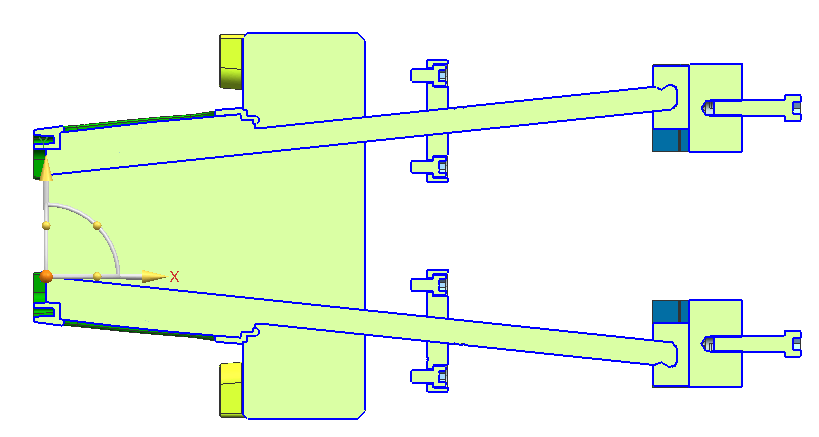

For simple molded products, ejection often requires a simple motion of ejector pins. These can work with conventional ejection mechanisms. Even complex designs can have

Plastic injection molding is a manufacturing process that demands efficiency in every aspect. From the feeding of plastic pellets to the ejection of formed products.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com