Why Important Of PLASTIC INJECTION MOLD VENTING

There are different ways to avoid air and liquid getting trapped in your part. Any liquid in the feed is likely to cause problems. Trapped

There are different ways to avoid air and liquid getting trapped in your part. Any liquid in the feed is likely to cause problems. Trapped

Injection molding has the potential to achieve uniform identical parts. Thousands to million parts can get made using injection molding. With the high capital investment

Karl Benz built the first automobile in 1886. It was not until the Second World War that the plastic industry boomed. This means that we

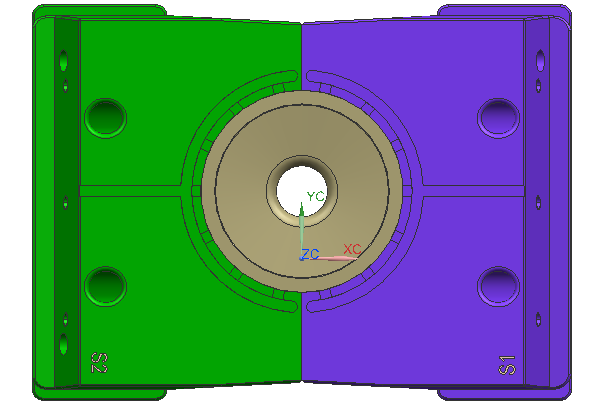

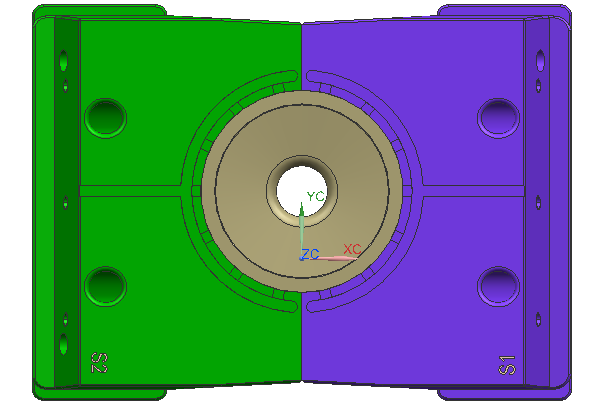

Mold appearance and dimension The water connector type is correct? The hole clearance for the water connector is enough? The out edge of the hole

Ejection of product from the mold is often overlooked in injection molding. In the ideal case project ejection happens in an instance. It is also

Polyethylene belongs to the polyolefin group of polymers. Other polymers in this group are polystyrene and polypropylene. Polyethylene is the most well-used class of polymers

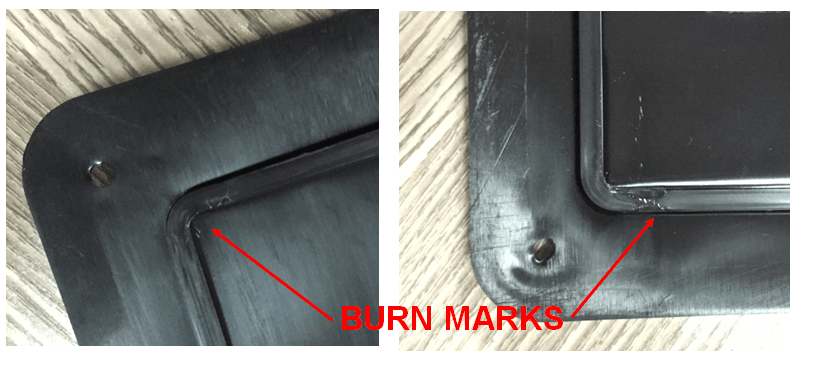

Injection molding can’t be exempt without defects and errors. There are many rooms for expensive defects. Some defects are unrepairable, but some can fix. Many

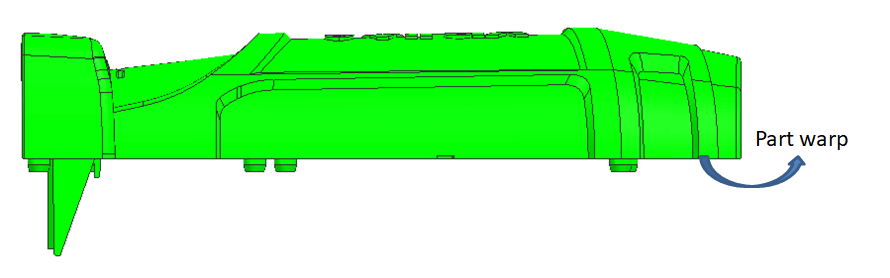

Warpage is one of the possible defects that can occur in injection molding. It results in the disfigurement of the product. A warped part most

Polymethyl methacrylate (PMMA) or acrylic is a well-established thermoplastic. It has come to be well known in the plastic industry. It is a good choice

Imagine living in a world where we do not fear quality. What if we all had a fearless reaction to the phrase quality. Imagine what

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com